Physical Electronics (PHI), the premier name in surface analysis offers analytical services using our state-of-the-art instruments. Our scientists have a deep knowledge of surface analysis applications and problem solving, and the benefit of always having access to the latest instrument technology. It is a winning combination to help you tackle your most challenging production, R&D, and engineering issues.

To discuss a particular project or to request a quote, please contact PHI at analysis@phi.com or call us at 518-650-1892 8 a.m.-5 p.m. CST

Common Applications

|

|

- Materials properties engineering and validation

- Surface defects and contamination

- Failure analysis and process control

- Coatings and interfaces

- Thickness and composition

- Nanomaterials and thin films structural characterization

- Metrological application

- Competitive analysis

|

|

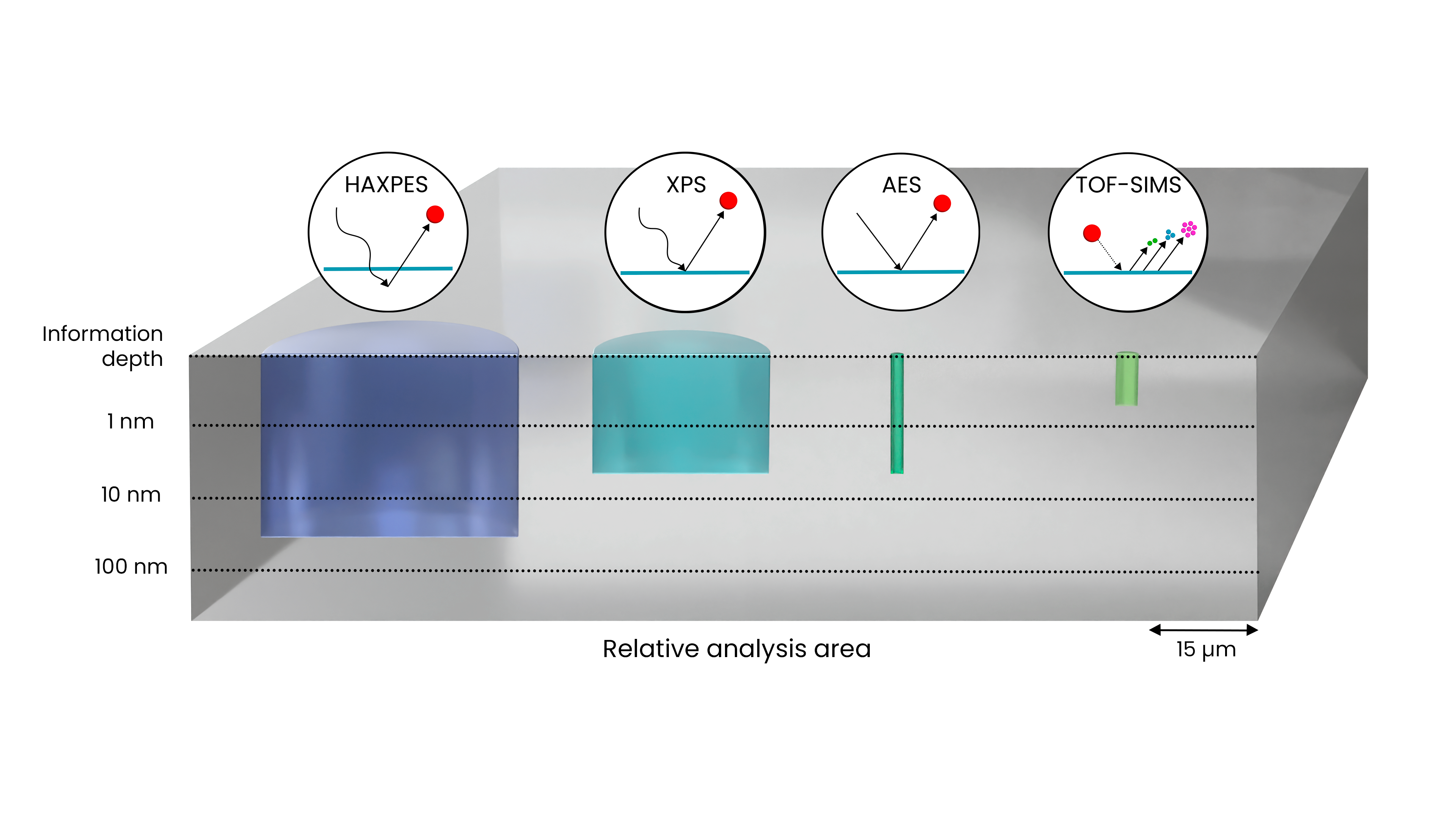

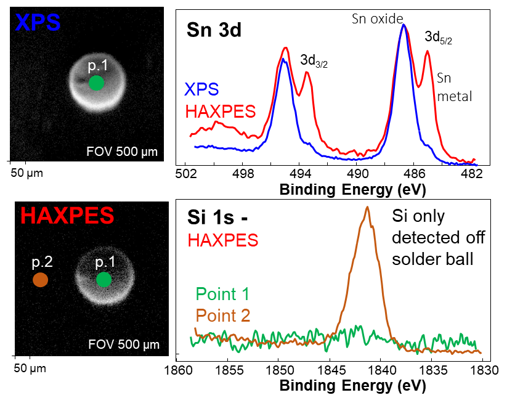

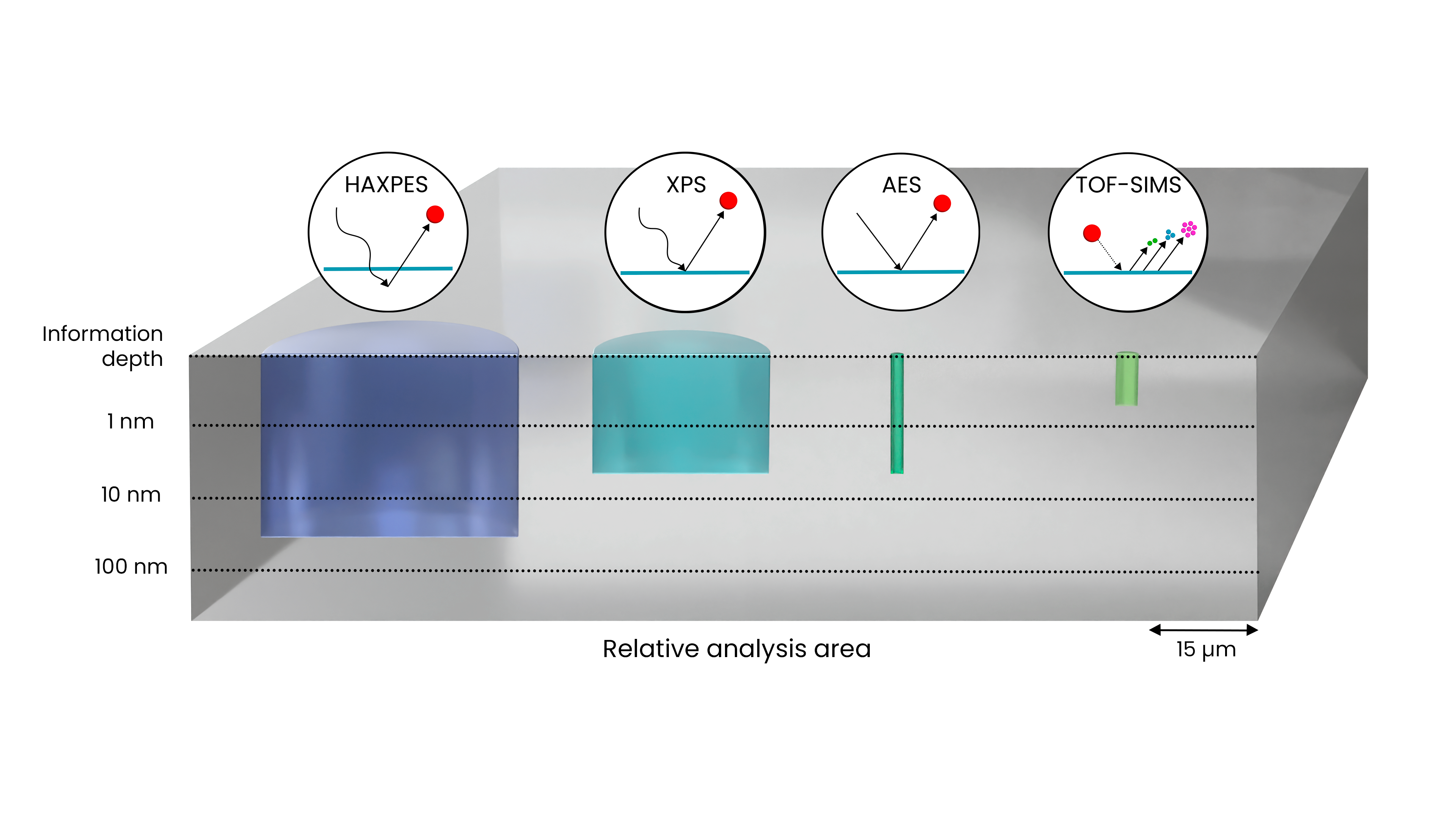

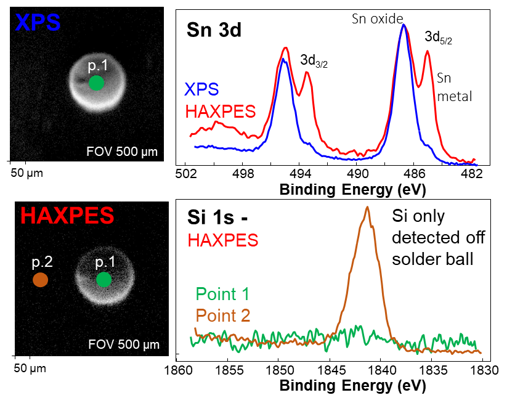

XPS - X-Ray Photoelectron Spectroscopy

- Quantitative elemental and chemical-state spectroscopy up to 10 nm below a material’s surface, which allows for probing film structures and buried interfaces

- Angle-resolved analysis for non-destructive multi-layer film thickness measurements (AR-XPS)

- Inert sample transfer vessel for air-sensitive samples

- Monoatomic argon (Ar+) and argon gas cluster ion beam (GCIB) for optimized sputter depth-profiling of organics, inorganics, and mixed materials

- XPS analysis is performed on the PHI Quantes Scanning XPS/HAXPES Microprobe instrument with Al Kα X-ray source

|

|

|

|

HAXPES - Hard X-Ray Photoelectron Spectroscopy

- Quantitative elemental and chemical-state spectroscopy up to 30 nm below a material’s surface, which allows for probing thicker film structures and buried interfaces

- HAXPES is a complementary technique available on the same instrument as XPS, allowing for analysis of the same region of interest on the sample surface

- Angle-resolved analysis for non-destructive multi-layer film thickness measurements (AR-HAXPES)

- Inert sample transfer vessel for air-sensitive samples

- Monoatomic argon (Ar+) and argon gas cluster ion beam (GCIB) for optimized sputter depth-profiling of organics, inorganics, and mixed materials

- HAXPES analysis is performed on the PHI Quantes Scanning XPS/HAXPES Microprobe instrument with Cr Kα X-ray source

|

|

|

|

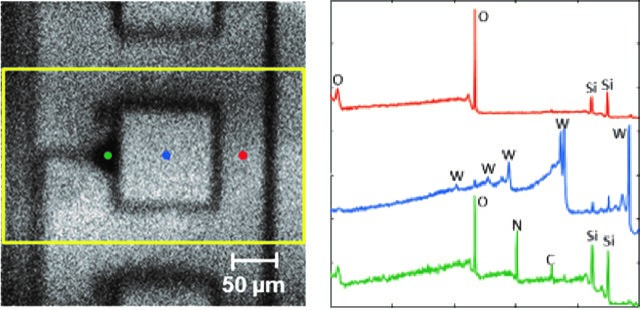

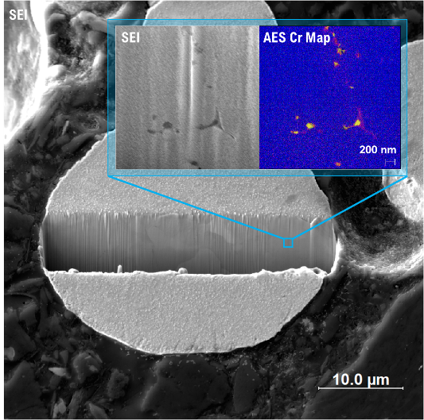

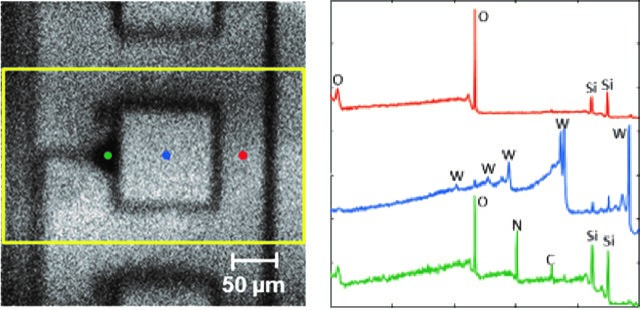

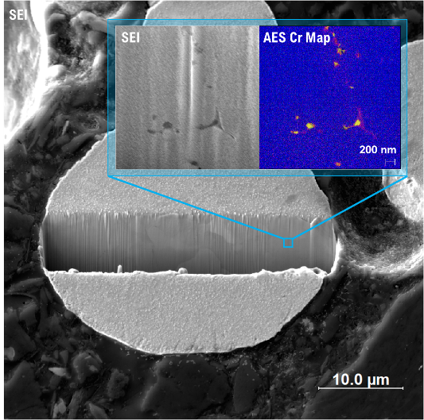

AES - Auger Electron Spectroscopy

- Quantitative elemental spectroscopy and nanoscale surface imaging up to 10 nm below a material’s surface, which allows for probing film structures and buried interfaces

- SEM-like (scanning electron microscopy) imaging with spatial resolution < 8 nm

- AES is the nanoscale counterpart of the traditional SEM-EDS (energy dispersive X-ray spectroscopy) technique

- Inert sample transfer vessel for air-sensitive samples

- Monoatomic argon (Ar+) sputter depth-profiling

- AES analysis is performed on the PHI 710 Multi-Technique Scanning Auger Nanoprobe

|

|

|

|

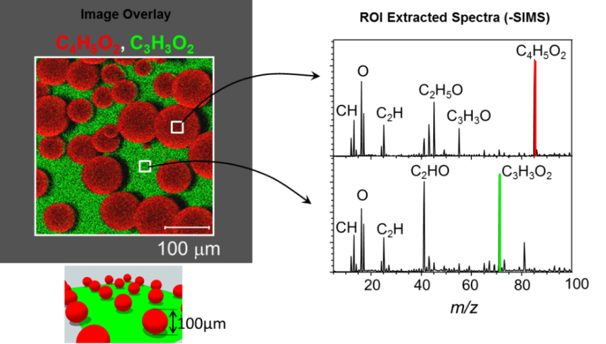

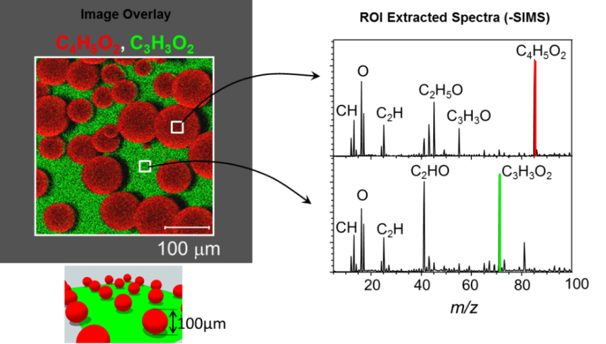

TOF-SIMS - Time-of-Flight Secondary Ion Mass Spectrometry

- Surface mass spectrometry, elemental & molecular imaging, and trace analysis

- Spatial resolution < 70 nm with 1-2 nm sampling depth below a material’s surface

- Detection limit of parts per million (PPM) and parts per billion (PPB)

- Inert sample transfer vessel for air-sensitive samples

- Multiple ion beams available for optimized sputter depth-profiling of organics, inorganics, and mixed materials: cesium (Cs+), oxygen (O2+), monoatomic argon (Ar+), gas cluster ion beam (GCIB)

- Tandem mass spectrometry (MS/MS or MS2) for unambiguous peak identification

- TOF-SIMS analysis is performed on the PHI nanoTOF II instrument

|

|

|

|

To discuss a particular project or to request a quote, please contact PHI at analysis@phi.com or call us at 518-650-1892 8 a.m.-5 p.m. CST.